Rigorous Quality Checks at Every Stage: Ensuring Excellence from Concept to Completion.

At National Manufacturing, quality is more than a benchmark — it’s the backbone of our operation.

Every component we produce undergoes rigorous inspection and testing to ensure it meets the most demanding industry requirements. With a relentless focus on precision and consistency, we deliver high-performance metal components trusted in mission-critical applications—where reliability is not optional.

Our dedicated Quality Assurance team is highly trained and empowered to drive excellence through Six Sigma and Lean methodologies. Certified Black and Green Belts lead our continuous improvement initiatives, ensuring data-driven decision-making and operational efficiency. In addition, our team includes ASQ-certified professionals who apply advanced tools such as Root Cause Analysis and Process Failure Modes and Effects Analysis (PFMEA) to proactively prevent issues and ensure long-term product reliability.

We conduct thorough validation studies—including Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ)—and apply structured quality frameworks like Advanced Product Quality Planning (APQP) and the Production Part Approval Process (PPAP). To ensure consistent performance, we carry out Statistical Capability Studies and maintain strict controls for lot traceability, record retention, and documentation.

Our commitment to quality is built into every phase of production:

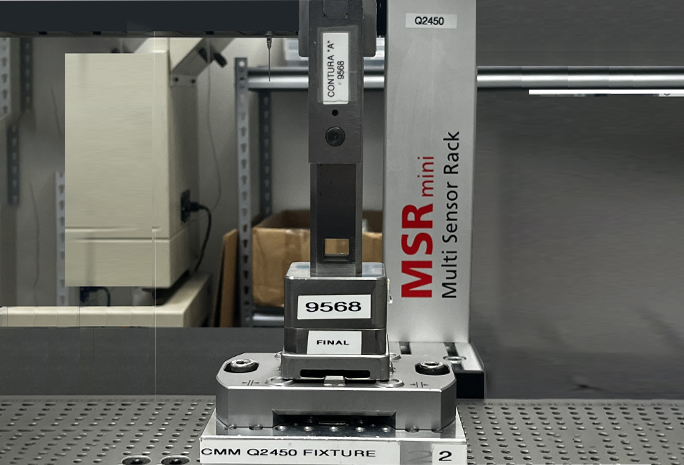

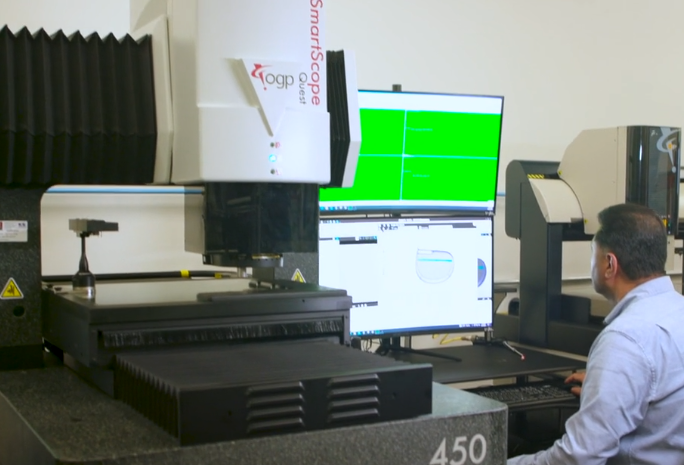

Precision Inspection & Testing: Advanced metrology systems confirm tight tolerances and critical dimensions.

Built-In Quality at Every Stage: Every process is monitored, optimized, and validated from concept to final output.

A Culture of Continuous Improvement: We continuously refine our methods and adopt best practices to elevate product integrity.

Customer-Aligned Standards: We tailor our quality systems to meet—and often exceed—application-specific requirements.

National Manufacturing is compliant with key industry specifications, including: ANSI/NCSL Z540-1-1994, ANSI/ASQ-Z1.4-2003(R2013), ISO 9001, AS9100, and ISO 13485.

At National Manufacturing, our unwavering commitment to quality is what sets us apart—delivering precision-engineered components you can count on.

We manufacture customized measuring tools that are essential for precision, ensuring each component meets exacting standards. Tailored for accuracy, our tools support rigorous quality control, reducing errors and enhancing product reliability.

Driven by quality, we are committed to using state-of-the-art measuring tools to ensure every component meets the highest standards. Our dedication to precision and reliability empowers us to deliver exceptional results, every time.

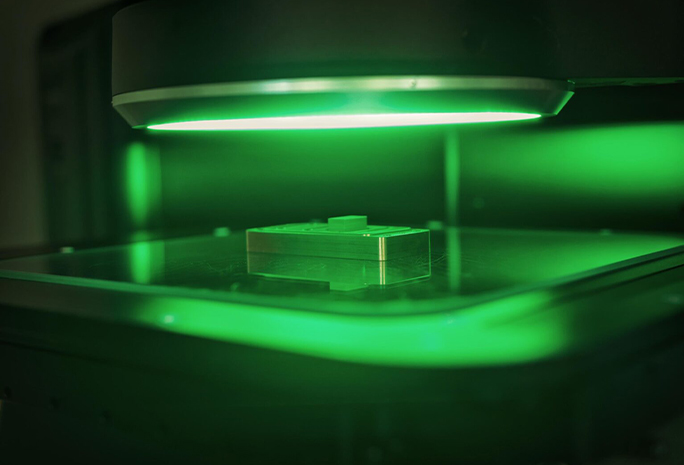

Utilizing state-of-the-art technology, we measure critical edge features with unparalleled precision, ensuring each component meets exacting quality and tolerance standards. Our meticulous approach enhances reliability and performance, delivering superior results for the most demanding applications.

Industries Served

Sitemap | Privacy Policy | Cookie Policy | Terms of Service | Copyright © 2025. | All Rights Reserved