Precision Machining of Complex Components, Crafted with Accuracy and Innovation

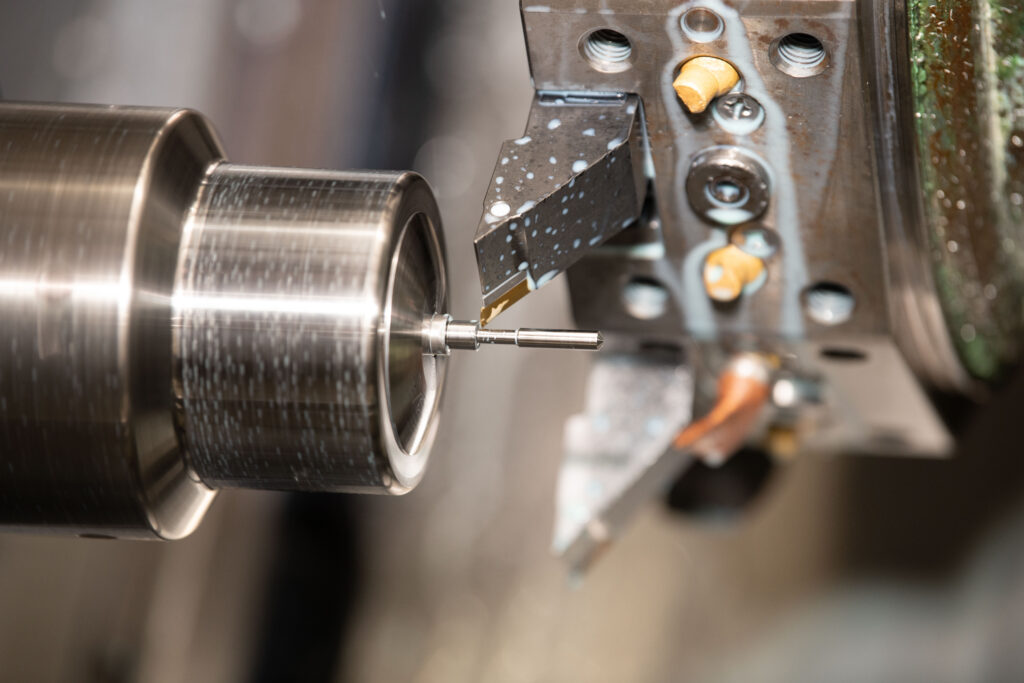

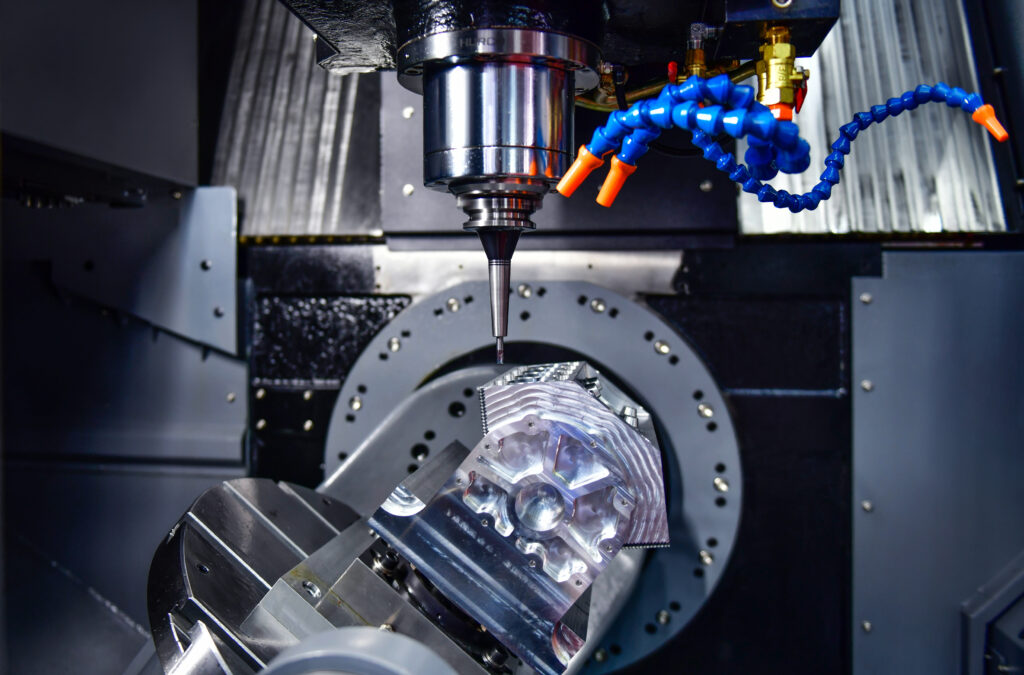

CNC Machining Excellence: Engineering Intricate, High-Performance Components

At National, our CNC machining capabilities are built to deliver precision, consistency, and performance—every time. We specialize in manufacturing high-tolerance components from hard-to-machine metals for mission-critical applications across aerospace, defense, and medical industries.

Our advanced multi-axis CNC equipment, including 3 and 5 axis milling and CNC turning centers, enables us to produce complex geometries with tight tolerances and superior finishes. Whether you’re prototyping or scaling up to full production, our skilled machinists and engineers ensure repeatable quality and fast turnaround.

Capabilities Include:

3-axis and 5-axis CNC milling

Dual-spindle CNC turning with live tooling

High-speed machining of complex shapes

Tight-tolerance machining of exotic metals and alloys

In-house tooling and fixture design for optimized precision

Unique size and tolerance capabilities.

Within the PrecisionX Group, our precision CNC machining capabilities are custom-tailored to produce components with unique dimensions and extremely tight tolerances for the most demanding applications. Utilizing state-of-the-art machinery and a team of skilled technicians, we deliver intricate details and exact dimensions that consistently meet rigorous specifications. Our advanced processes empower us to manage complex geometries and customized sizes, ensuring every component is manufactured with unparalleled accuracy. Driven by a steadfast commitment to precision and quality, we deliver reliable, high-performance parts for critical applications across a range of industries.

As a PrecisionX Group company, we bring the added value of cross-industry expertise and vertically integrated processes to every project. From initial design support through final inspection, National is your trusted partner for complex CNC-machined components that demand uncompromising accuracy and quality.

CNC MILLING CAPABILITIES, include…

| 3-Axis with Trunnion | 5-Axis High-Precision | 3-Axis with Rotary | |

| 3 Axis Work Envelope (in) | 64″ x 32″ x 30″ (X, Y, Z) | N/A | 19.68″ x 15.74″ x 12.9″ (X, Y, Z) |

| Max Part Weight (lb.) | 2,000 | N/A | 660 |

| 5 Axis Work Envelope (in.) | 19″ x 18″ (Dia, Length) | 7.87″ x 6.2″ (Dia, Length) | 11″ x 14″ (Dia, Length) |

| Max Part Weight (lb.) | 200 | 33 | 220 |

| Spindle RPM (min-1) | 12,000 | 40,000 | 10,000 |

| Spindle Power (HP) | 30 (Cont.) | 10 (Cont.) | 15, 5 (Peak, Cont.) |

| Spindle Torque (ft-lb) | 22.4 (Cont.) | 1.3 (Cont.) | 39 (Peak) |

| Surface Finish Min (Ra) | 12 | <1 | 2 |

| Accuracy (in.) | 0.0001 | 0.00002 | 0.0002 |

| Repeatability (in.) | 0.0001 | 0.00002 | 0.000078 |

CNC TURNING CAPABILITIES

| Work Envelope (in.) | 14.17″ x 23.6″ (Dia, Length) |

| Main Spindle RPM (min-1) | 3,500 |

| Main Spindle Power (HP) | 30, 25 (Peak, Cont.) |

| Main Spindle Torque (ft-lb) | 369, 310 (Peak, Cont.) |

| Sub Spindle RPM (min-1) | 5,000 |

| Sub Spindle Power (HP) | 20, 15 (Peak, Cont.) |

| Sub Spindle Torque (ft-lb) | 92, 51 (Peak, Cont.) |

| Live Tool Spindle RPM (min-1) | 6,000 |

| Live Tool Spindle Power (HP) | 10, 5 (Peak, Cont.) |

| Live Tool Spindle Torque (ft-lb) | 30, 13 (Peak, Cont.) |

Industries Served

Your partner in excellence.

Sitemap | Copyright © 2025. | All Rights Reserved